|

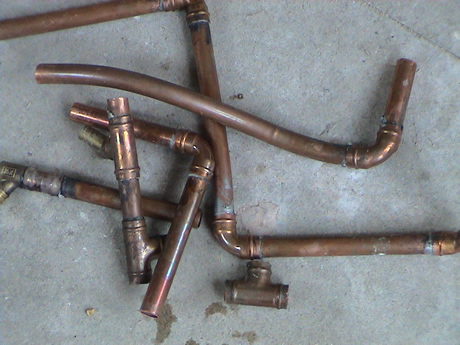

bathroom and plumbing disasters Remember my rather smug mention of copper tube last summer? Steve, my friend and building Virgil to my Dante told me how easy plastic pushfit connectors were but I insisted in getting out my blowtorch and soldering every joint. At the time things seemed rather strange. That ring of solder that appears around joints when you heat to the right hellish heat just never seemed to shine. The copper just went black. Now that the pipes are full of water at pressure, one by one they started to leak; so after chipping off my carefully glued wall tiles and cutting out sections of bathroom wall, I have replaced most of them with plastic push fit connectors. They are so easy. No spanners to get into awkward places, no joints to fail to solder, and you can just dismantle them when you want without your hacksaw. the sad end of my soldering

the toilet is a whole other story. Ceramics made in the United Arab Emirates and stuff inside the cistern made in France. It was really cheap and it showed. When opening the package, the cistern lid fell out breaking the plastic button on top which was pre connected to the innards with wire. I glued it back with super glue (and it has held out for 4 years so far).

through to the future sauna. Floor tiling into the sunset to go back to the beginning click here to go back to February click here to go forward to May 2004 click here

|